Don’t make the mistake of using the wrong screw for the wrong purpose. It can result in a number of problems, including (but not limited to): poor/weak construction, splitting wood, wasted material, etc.

Relevant Links

Buy Kreg Pocket Hole Screws Here

What is the Difference?

There are many different screws available to use, but I’m mostly concerned with wood screws. Specifically, pocket hole screws vs regular screws.

I do a lot of pocket hole construction for a number of reasons: it is easy and quick, good for beginners, and it works well.

Kreg Tool is an industry leader in this category; they make a bunch of pocket hole joinery tools and a bunch of different screws especially designed for pocket hole construction.

The question will arise: can’t I just use regular wood screws? This happens when you look down at your box and you realize you’re out of the special Kreg screws.

I’ll address this question and a few others in this post. I’ll cover the differences between these screws and go over the different applications for each.

About Pocket Hole Construction

Pocket hole construction is a quick and strong way of building projects out of wood. If you have any of Kreg’s products then I’m sure you are familiar with how it works.

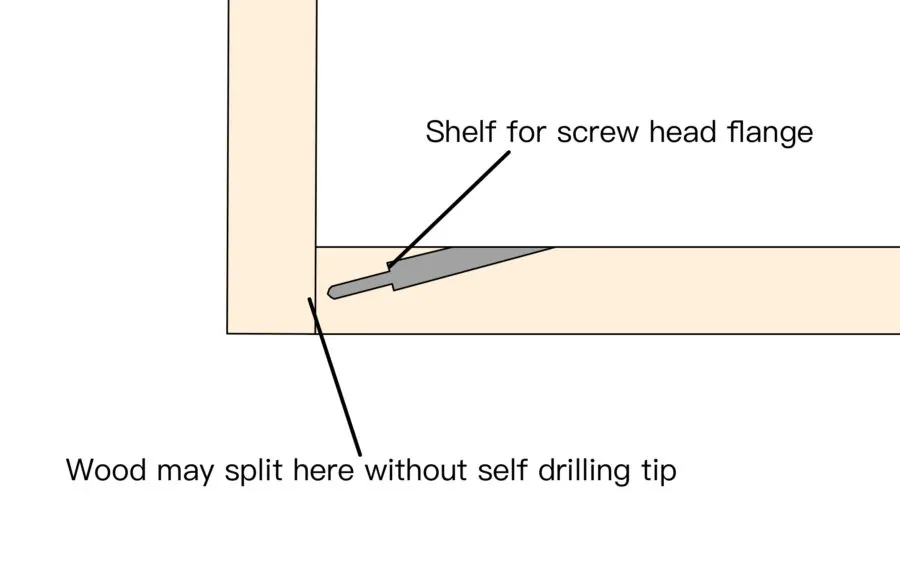

Take a look at the diagram below to see two important features of a pocket hole setup. These aspects warrant the need for a specific type of screw.

I will go into depth about why these two parts of a pocket hole are important in just a second. First, look at a regular screw so I can point out the differences when compared with a regular screw:

This is a general use wood screw that you may buy at any hardware store. These serve an important purpose, although they are not commonly used in woodworking like building furniture.

If you were to use one of these in a pocket hole, then you run the risk of the joint failing in a number of ways. This is because it is the wrong screw head type and it does not have a self drilling tip.

Screw Head Type

The head type on the regular screw is wrong for this situation. The screw in the picture above has a “bugle head” type. That is the curved portion underneath the flange. It curves down to the shank of the screw. This is meant to help countersink it into the surface when you drive it into a piece of wood.

It is meant to lay flat like in this picture:

The reason this is a problem in a pocket hole is because the screw needs to stop at a specific depth or it will run out the other side of the board.

If you weren’t aware already, different boards require different depths of pocket holes, and thus, different screw sizes. I have a chart on that here.

You need the screw to stop at the right depth. This is set by the drill bit when you drill the pocket hole. You can see the flange in my diagram above. Lets look at a pocket hole screw:

From what I can tell, there are a number of different names for this type of head. As you can see these have a flat flange on the head. This is known as a “washer”, “flange”, or “round” head. When it hits the edge inside the pocket hole it will stop at that predetermined depth.

Self-Drilling Tip

Some wood and metal screws come with a tip that is self tapping. This means that the end of the screw has a small blade cut into the end of the threads. You can see this groove in the picture above.

This helps clear a path for the screw when the hole is not pre-drilled. When using pocket hole construction you can really only pre-drill where the pocket hole drill goes. It is too difficult to try and drill a hole into the other piece because you don’t know exactly where it needs to be.

A regular screw without this self-drilling feature might split (crack) the wood when you drive the screw into the piece. This is especially likely if the screw location is near the end of a board.

Advantages of Using Kreg Screws

There are several advantages of using Kreg screws in your woodworking shop.

One is the fact that they have a myriad of sizes and types. For example, they make a coarse threaded screw for soft woods and a fine threaded screw for hard woods.

They also provide a bunch of different sizes to meet the requirements of your project. It makes things go together much quicker and easier than ever before.

Combine these screws with other Kreg Tool products and you will be building things in no time. It simply helps standardize your materials from one task to the next.

One nice feature of Kreg Screws is that they are driven with a square recess bit. This type of driving recess is also called a “Robertson” style.

It has four driving edges like a “Phillips” head, but the sides are not sloping towards the middle; instead they are relatively straight. It helps prevent the bit from sliding out and stripping the head like can happen with a Phillips head.

Kreg even makes a long bit designed for driving these into the pocket holes. Although they are not the only ones that make this type of stuff, it is great to have it all available in one place.

Conclusion

You can see here that regular wood screws are not the same as pocket hole screws. There are certain features that separate the two. These features are critical to the performance of pocket hole joinery. Such a seemingly small part of your project can make a huge difference in the outcome.

When choosing which screws to use for your project it is important to consider what the screw was originally designed for. A screw meant to countersink into wood is not going to perform well when asked to stop at a predetermined distance.

I’m not saying you can’t make this work, just that it is definitely not ideal.

To buy Kreg pocket hole screws, go here.

If you would like to dive more into woodworking tips and projects, check out my page on getting started. It is meant mostly for beginners, but almost anyone can benefit from reading through.

Also, if you are looking for projects to get started on, look at my easy woodworking projects post.

Ty,

You may have missed a critical difference between pocket hole screws and other types of screws that effects the clamping action. If you notice, the shaft that is closest to the head has no threads. This allows the screw to pull the two pieces of wood together. I am sure we all have had the situation where a “drywall” screw is used and even though the head is driven in the two boards don’t always come completely together. Otherwise great article.

Thanks.

Great point Dave. I’ve always found the clamping action of Kreg screws to be really effective, and the detail you pointed out explains why. I remember the days where I would build things with drywall screws…not the best to say the least.

Ty,

I’m in a situation where I am using a hardwood (Oak) and have already drilled my material which is pocket holes into 2×4’s that are then going to be screwed to a 4×4. I realized only after that Kreg doesn’t make / offer 2-1/2 screws that are fine threads (only coarse, which they say are only for softwoods). What should I do here in terms of a 2-1/2 screw?

Great question, I would suggest testing out using the coarse screws on some scrap oak first. Fine threads are meant to prevent splitting the wood and stripping of threads (and breaking of screw from too much torque). If none of that happens then they should work.

Two things I would do: 1. get some wax (like toilet ring wax) and coat the screw before you drive it. 2. Don’t drive it all the way in at once. Work it back and forth a little and then tighten it down. If it starts to bind take it out and put more wax on.

(I also suggest glueing these joints in addition to your screws).

This is not guaranteed to work and I see where others have had this issue as well (Like HERE)

Like they mention on that page, your other option is to drill a different pocket hole for 1-1/8″ and use the fine thread 1-1/2″ screw. Hope it works out!

Thanks for the good tutorial. You just proved an old dog is still teachable.

ED