When you go to buy a tool you may see advertising promoting the “brushless motor” of the tool. While it’s not vital to know what this means, I think it’s good to know what you are buying.

Brushless motors are everywhere these days. There’s a reason why tool companies are manufacturing more products with them. You can find them in cordless drills, impact drivers, rotary hammers, etc. Here’s everything you need to know about brushless motors before you buy your next power tool.

What is a Brushless Motor?

In the mechanical world of electric motors, you have brushed and brushless motors that are either alternating current (AC) or direct current (DC). As the name suggests, brushless motors don’t have any brushes and use DC electricity for power. This design offers several advantages.

Brushed motors have been around since the early 1900s, with brushless first surfacing sometime during the 1960s. Motor manufacturers were looking for a solution to improve stationary torque power while reducing general wear and tear (both very beneficial in power tools). This improved design has slowly made its way into affordable tools from brands like Ryobi and Milwaukee Tool.

How Does a Brushless Motor Work?

This section is a brief overview and may be somewhat confusing, but I will do my best to describe how it works.

If you have any prior knowledge about DC motors, you may know that the brushes in brushed motors are there to deliver electricity to the engine’s copper coils. Since brushless motors don’t have any components on the collector, there’s no need to maintain or replace any brushes and other electrical elements.

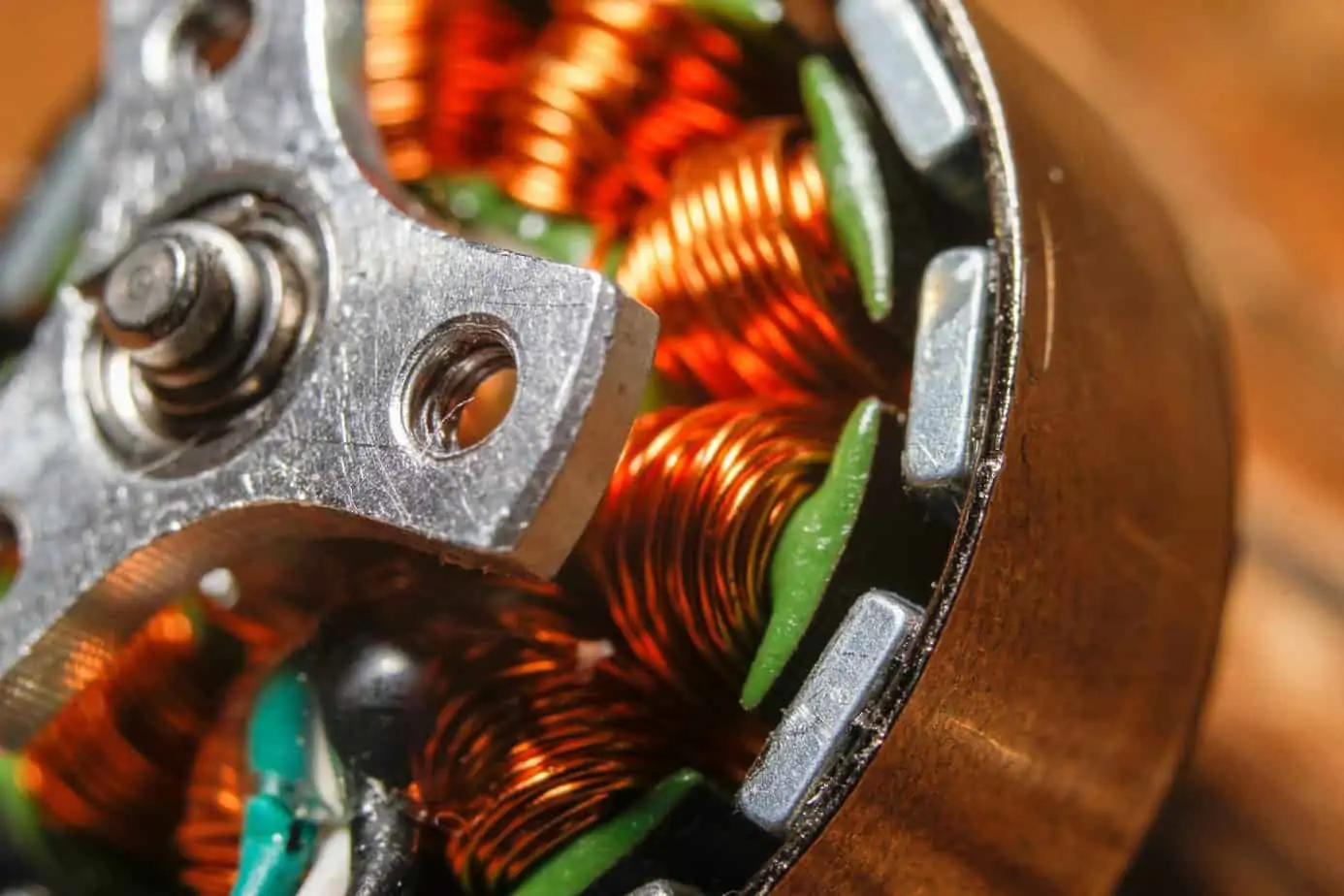

The brushless motor has a rotor containing permanent magnets, and this is essential, considering there are no electrical contacts, as we mention above. Its stator comes with electromagnets covered in windings and coils.

Since a brushless motor can have both a rotor and stator with electromagnets, it can produce a much stronger magnetic field than brushed motors. As a result, brushless motors have a higher mechanical power density, which allows them to produce higher torque while stationary.

The permanent magnets within the rotor are attracted to the electromagnets without ever making contact. When the electricity flows into the coil, the opposite poles of the stator and rotor are attracted to each other. Each time the rotor gets close to the coil, electricity will jump to the next coil, so on and so forth. An internal sensor and an electronic controller controls this process.

Understanding the Different Types of Brushless Motors

Fundamentally, there are two different types of brushless motors: outer rotor motors and inner rotor motors. Both motors work using the same principles, but differ in design.

Outer Rotor Motors

The outer rotor motor’s design is likely the most complex of the two. In this motor, the winding is within the rotor and rests in the motor’s core. Each of the magnets in the rotor is responsible for trapping heat, which doesn’t dissipate any energy. Outer rotor motors generally have lower torque and can function on a lower-rated current.

Inner Rotor Motors

Opposite of the outer rotor motor, this motor’s design has the rotor inside the motor with the stator winding around it. Since the rotor is in the motor’s core, the magnets don’t insulate any heat, which dissipates quite quickly. As a result, inner rotor motors produce a powerful torque, making them a popular choice among tool manufacturers.

What Are Brushless Motors Used For?

Since brushless motors have more efficiency than brushed, they are far more favorable. Brushes wear down, cause potentially dangerous sparks, and have a shorter lifespan. As a result, you’ll likely find brushless motors in most modern devices that require little noise and low heat (power tools, washing machines, air conditioners, etc.)

Some companies even use them to power service robots. However, this process requires more monitoring for safety reasons. Without a doubt, brushless motors have several advantages (stay tuned), and that’s why they are in a vast majority of household devices.

Not only are they suitable for personal devices, but they are making their way into more industrial work environments. As long as there’s a need for less noise, no heat, and minimal maintenance, brushless motors will be useful.

Brushless Motor Sizes

Brushless motors come in various shapes and sizes. If you plan on getting one, it’s essential to know about each size and what they’re suitable for. Unfortunately, brushless motor manufacturers aren’t the most creative when it comes to naming the different sizes, so you’ll need to rely on the 4-digit system. Here’s a breakdown of each of the sizes:

- 1806: These motors are usually in mini quads, which contain 3 to 4-inch propellers.

- 2204: The 2204 used to be one of the most popular sizes on the market. Nowadays, you rarely see them. These motors contain 5-inch propellers.

- 2205: This is the most compact brushless motor on the market. The 2205 is small and easy to install in household devices.

- 2206: The 2206 is supposed to add additional thrust. Manufacturers can now add an extra 15% of thrust while using these brushless motors.

- 2407: These are the “do all end all” for thrust capabilities. If you aren’t satisfied with the thrust from a 2206, then the 2407 will surely do the trick.

What About the Winding Size?

As a general rule of motor mechanics, thrust is proportional to power. If the motor receives more energy from the power source (battery), you’ll have a more powerful device. You can do some things to improve the amount of power you get with your brushless motor, and the easiest is to get a motor with a higher RPM.

Motors with a higher RPM have shorter windings, which reduces resistance and gives the current power a big boost. However, as the windings become shorter, you’ll need to sacrifice torque and heat. You can only accept so much energy before you start to lose efficiency.

If you want to increase the power without sacrificing efficiency, add more windings. You can also try adding more copper to the windings for stronger conduction. This process reduces electrical resistance and allows more current to flow through the motor. However, the more copper and windings you add, the heavier the motor will be.

On a side note, adding additional components to your motor might compromise its design. You could end up damaging the stator, making your motor less effective. With that in mind, adding more power to your motor isn’t a bad idea. You only want to make sure you find the right balance before you lose efficiency.

The Electronic Speed Controller (ECS)

The ECS is responsible for controlling the speed of the motor. It’s a vital part of your brushless motor, so it’s wise to understand how it works. In simple terms, the faster the ECS, the faster the motor.

The ECS essentially controls the power of the magnetic connection. Therefore, you can use it to speed up or slow down your motor. This intricate electronic speed controller is one of the several reasons why brushless motors are a superior option. Other conventional motors don’t have an accurate way of controlling speeds, limiting their functions.

Advantages

Above, we mention that brushless DC motors have several advantages over conventional brushed motors. Some of the significant advantages include:

- Since brushless motors don’t have any brushes, there’s no need for the high maintenance and brush replacement cost.

- Brushless DC motors are more efficient than brushed motors. The higher efficiency is that brushless motors have more speed control due to the internal electronic controller and sensor.

- Brushless DC motors have a longer lifespan. On average they will last roughly six times longer than a traditional brushed motor.

- Since there aren’t any brushes, sparks are less common or nonexistent. Sparks can be potentially dangerous if you’re working around gasoline or other flammable compounds.

- They are compact, lightweight, and can provide an impressive amount of torque power.

- Produce less noise when operating than other traditional DC motors. As a result, they are great for household devices such as computers, washing machines, and air conditioners.

The advantages of using a brushless motor far outweigh the disadvantages, but they are perfect. Although these motors are ideal for several different devices, they come with a few disadvantages explained below.

Disadvantages

- They can be more costly than brushed and traditional motors.

- When the motor is operating at low speeds, vibrations can be a bit intense. However, as soon as the speed increases, the vibration starts to go away.

FAQ

How Long Do They Last?

There’s no doubt that brushless motors have one of the most extended lifespans. Any standard brushless motor should last you tens of thousands of hours. For comparison, a brushed motor will only last between 1,000 to 3,000 hours if you’re lucky. The longer lifespan is because there aren’t any brushes that wear down while the motor is operating.

Why Are Brushless Motors So Expensive?

There are a few reasons for the higher price tag. Many think that a brushed motor would be more costly, considering it has a far more elaborate construction process and design. However, brushless motors contain high-quality components such as premium electromagnets, sensors, and electronic controllers. Therefore they are more expensive.

Are Brushless Motors Waterproof?

In short, no they are not waterproof. The motor’s general design is water-resistant, but there are far too many metal components that are susceptible to corrosion if wet for prolonged periods. If the motor is submerged in water for too long, the bearings will wear down and rust and hinder its performance.

How Do You Control the Speed?

You can use variable voltage to control your brushless motor’s speed. This also allows you to control the torque and other characteristics of the motor.

Conclusion

It should be clear why more and more tools and manufacturers are using brushless motors for their electrical motor needs. It is also becoming much more affordable to buy these tools as they are everywhere now.

While most of this article is not critical to your DIY activities, it is nice to have some background knowledge on the tools you are using. This is especially helpful when you decide to go shop for new tools.